Vortex Freeze-Dried Technology (VFD)

ADVANTAGES OF OUR PROPRIETARY PROCESS

- Increased bio-activity by sustaining cellular and molecular integrity

- Increased bioavailability due to these factors:

- Natural micronization – small particles are easier to absorb

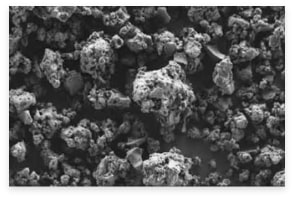

- Porous particle structure provides increased surface area per unit of weight (see photo below) and is more easily absorbed

- Consistent drying with no exposure to heat at any time during the process

- Sublimation and micronization accomplished in a one-step process – faster production time and decreased risk of contamination in handling

- Finished powder with exceptionally low moisture levels (normally under 2%) are better preserved

Science recognizes the freeze-dry process as the most effective method to preserve bio-active substances including herbs and botanicals. Freeze-drying became well known near the end of WWII when it was used to transport blood plasma to soldiers on the front lines. When snake venom is collected to make anti-venom it is freeze-dried. Most scientific laboratories have small desktop freeze dry machines to preserve samples with the least possible disturbance to their chemical composition. The product is dried while it remains frozen. Sublimation removes water and only water but this water does contain terpenes and traces of other active compounds and VFD can save the water that has come from inside the herbs in a 100% naturally soluble liquid form. Thai Freeze Dry is truly where nature meets science.

MORE ADVANTAGES

While these same herbs can be found growing elsewhere, our unique processing (VFD) is where the magic is made. It provides you with both unique selling points as well as barriers to competition.

The biggest challenge of conventional freeze-drying functional superfoods and nutraceuticals is the high cost of machinery, operational costs, huge energy usage and small quantities produced. These factors combine to make conventional freeze-drying slow and expensive.

In conventional freeze-drying the product is laid out on trays and the trays are placed on racks inside the product chamber. The exposed surface area (the drying surface) is limited, and only a small quantity of raw material can be processed.

In our VFD process, the product is not sitting motionless on trays but is flying around inside the product chamber in a vortex. This dramatically increases the exposed surface area which, in turn, increases the rate of heat exchange allowing very much larger quantities to be dried faster.

Solid particles- Conventional Freeze-Drying

Soft, porous particles from VFD

While our process increases quantity and efficiency (expressed in lower costs) we also increase the quality. In the case of conventional freeze-drying the dried product must be mechanically ground into a fine powder. This intense grinding process can develop heat (due to friction) and hemorrhages the cells. With Vortex Freeze Dried Technology, the motion of the deeply frozen particles along with the sublimation of the ice structure that holds the particles together results in a fine powder that requires minimal or no grinding. The resulting porous particle structure is more bio-active with better preserved natural ingredients and more bioavailable as it is more easily absorbed and metabolized.

To learn more about our Vortex Freeze-Dried process, please click here